Revolutionizing Open-Pit Coal Mining in Indonesia with Digital Twin

PT Pamapersada Nusantara (PAMA) is a mining company in Indonesia. It owns a large open-pit coal mine with an area of 466.5 hectares. For a long time, the mining sector faced problems such as backward management, intensive labor, and low production efficiency.

To better promote its digital transformation, PAMA took the initiative to introduce GIS technology and created an intelligent mining industry solution, greatly improving PAMA’s information management level.

Open-pit coal mines often have large production capacity and large-scale equipment, resulting in high labor intensity and a low degree of informatization. In recent years, with the increasing demands of enterprises for safe production, high efficiency, and low cost, the introduction of advanced communication technology and intelligent control technology has gradually garnered attention.

PAMA’s management difficulties lie in the inability to monitor open-pit coal mines in real time, the complexity of the management and approval process, and the ineffective use of spatial information. In response to these needs, the GeoMining solution was created and provided by SuperMap (hereinafter referred to as the “solution”).

It uses geographic intelligence to empower decision-making, monitoring, approval, information visualization, and other aspects of mining operations. The solution has significantly helped reduce the time taken for process approval, and guaranteed the safety of mining and production activities, thereby reducing labor costs and time costs, and increasing profits.

How on earth does the solution work? The following four measures, from management to operation, are what it provides to reduce costs and increase efficiency.

- Digitization of traditional manual processes

In the solution, complex data, such as data from drilling sensors and excavator guidance sensors, can be unified and integrated into the cloud through the network, and displayed on the web map. Decision-makers can use this information to enhance the daily mining plan and quickly initiate the plan approval process on the web or mobile end, then synchronize the planned tasks to the corresponding personnel’s client.

“The geo-mining system with GIS software allows real-time tracking of equipment and vehicles, optimizes information on daily production activities and provides an overview of the size and area of the work location,” PAMA introduced in an interview.

- Mining progress updated in real-time

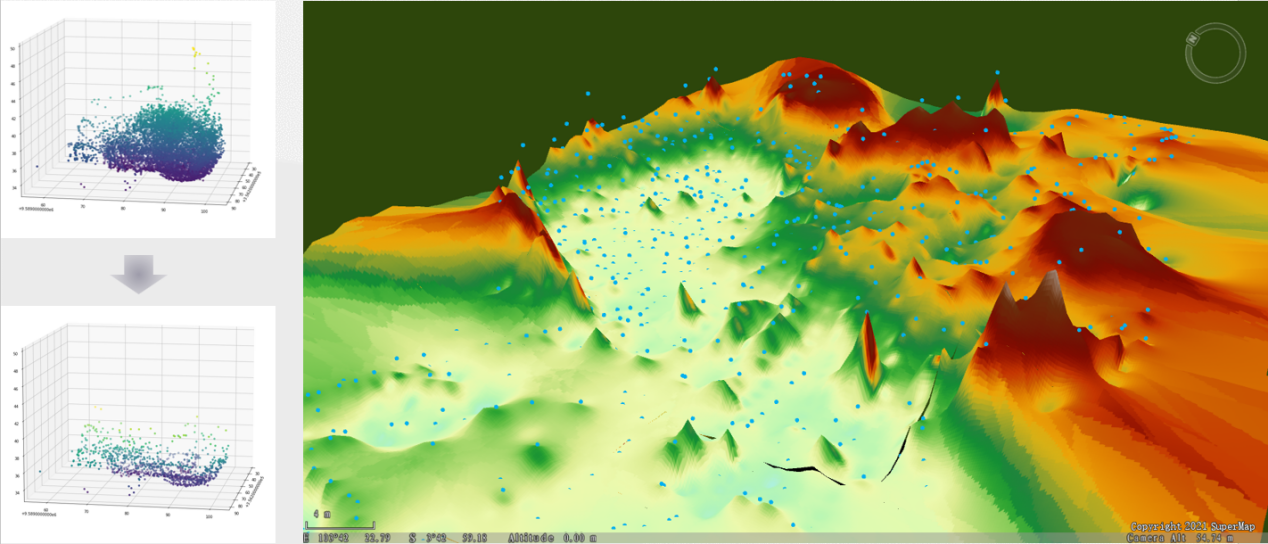

The traditional way of mine management usually requires professional engineers. With digital twin technology, the solution provides map services, spatial data services, and 3D services based on SuperMap iServer to reproduce the real scene of open-pit coal mines.

At the beginning of the mining project, the terrain data can be imported, and geographical grids of different degrees of fineness can be constructed according to specific projects. Through real-time streaming data of location information, the grid data can be continuously updated.

The daily updated terrain data saves the labor of frequent manual measurement. The visualization of mining progress, updated at short intervals, along with the automatically formed electronic terrain log, can provide decision-making support for the subsequent mining work.

- Digital management of mining equipment

Using smart sensors, the location of various equipment in the mine can be synchronized to the cloud. Referring to the mining process and plan, the solution adopts geo-fence technology to specify the operating area of the equipment. At the same time, the precise equipment entry time and departure time will be monitored. Through accurate management, the utilization efficiency of equipment can be effectively improved, the project cycle can be shortened, and costs saved. Geo-fence technology also provides an early warning function. “The system helps daily operations by monitoring mining activity near mine areas and sensitive environments, ensuring compliance, and generating alerts for action and guidance,” PAMA said.

- Intelligent management of mining personnel

By uploading the information of mining personnel to the cloud in real-time, managers at the control center can view, in SuperMap iClient, the current position and movement track of mine workers. Abnormal situations and safety risks can be detected and dealt with in a timely manner.

The detailed personnel information can help achieve more refined management of the operation plan, optimize the operation process, and thus improve the quality of operations. Compared to taking action afterward, it is more effective to check in advance on the platform whether the planned task has exceeded the budget or the expected time.

Read More: Revolutionizing Open-Pit Coal Mining in Indonesia with Digital Twin